Beer is one of the oldest and most popular alcoholic drinks in the world. Its unique flavor and refreshing qualities have made it a staple in many cultures. However, have you ever considered how beer is produced? The process of making beer involves several meticulous steps, each contributing to its taste, aroma, and quality. In this article, we will explore the beer-making process in detail.

1. Selecting the Ingredients

Water, malted grains, hops, and yeast are the main components of beer. The flavor of beer is directly influenced by the quality of these ingredients:

- Water: The main component of beer, influencing its texture and taste.

- Malted Grains: Usually barley, malted grains provide sugars that ferment into alcohol.

- Hops: Hops add bitterness, aroma, and act as a natural preservative.

- Yeast: Yeast is responsible for fermentation, converting sugars into alcohol and carbon dioxide.

Choosing high-quality ingredients is crucial for brewing a flavorful and aromatic beer.

2. Malting the Grains

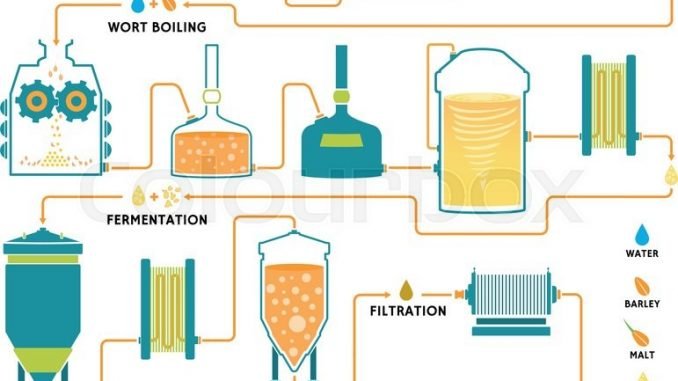

Malting is the first step in transforming raw grains into malt. The grains are soaked in water to encourage germination, then dried in kilns. This mechanism initiates the activation of enzymes that convert starches into fermentable sugars. The degree of roasting during malting affects the color and taste of the final beer, ranging from light and crisp to dark and rich.

3. Mashing the Grains

Once malted, the grains are crushed and mixed with warm water in a process called mashing. This creates a thick, sweet liquid known as wort. During mashing, enzymes break down the starches from the grains into simple sugars, which are essential for fermentation. The temperature and timing of mashing significantly influence the flavor profile of the beer.

4. Boiling and Adding Hops

After mashing, the wort is boiled in a large kettle. Boiling sterilizes the liquid and extracts flavors from the hops. Hops are added at various stages of boiling to balance sweetness with bitterness and to enhance aroma. Some beer recipes also include additional spices, fruits, or herbs during this stage to create unique flavors.

5. Fermentation

The wort is cooled and placed in fermentation tanks after it has been boiled. Yeast is added to the wort, and fermentation begins. During fermentation, yeast consumes sugars and produces alcohol and carbon dioxide. This stage can last from a few days to several weeks, depending on the type of beer being brewed. There are two main types of fermentation:

- Top-Fermentation (Ale): Yeast rises to the top; shorter fermentation time; produces fruity flavors.

- Bottom-Fermentation (Lager): Yeast settles at the bottom; longer fermentation; produces clean, crisp flavors.

6. Conditioning and Maturation

After fermentation, the beer is conditioned to develop flavor, clarity, and carbonation. This can occur in tanks, barrels, or bottles, depending on the brewing method. During this period, any remaining yeast settles, and unwanted flavors are reduced. The length of conditioning might range from a few weeks to several months.

7. Filtration and Packaging

Before packaging, beer is filtered to remove solids and achieve a clear appearance. It is then carbonated if necessary, either naturally or artificially. Finally, the beer is bottled, canned, or kegged for distribution. Proper packaging ensures the beer maintains its flavor, aroma, and freshness until it reaches the consumer.

The beer-making process is a blend of science and art, combining carefully selected ingredients with precise techniques. From malting grains to fermentation and conditioning, each step plays a crucial role in creating the perfect brew. Whether you enjoy a light lager or a robust stout, understanding the process adds appreciation for this beloved beverage.

What is Blended Whisky and Single Malt

Read Also: Recipe Cuisine

![]()